of rp_featop.jpg)

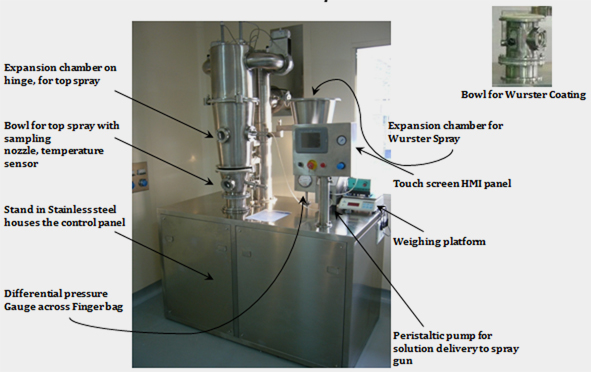

Salient Features

Safety

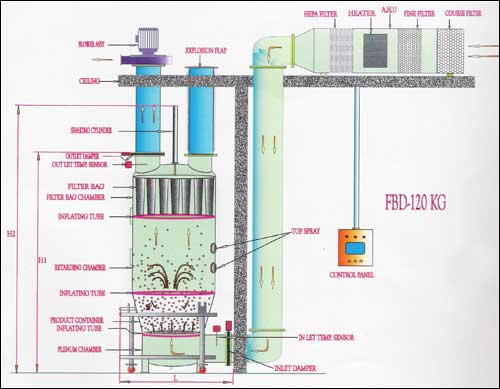

| Model | SSE FBD 10 | SSE FBD 30 | SSE FBD 60 | SSE FBD 120 | SSE FBD 150 | SSE FBD 200 | SSE FBD 250 | SSE FBD 300 |

| Bowl Volume (Liters) | 35 | 110 | 200 | 425 | 500 | 625 | 780 | 925 |

| Batch Size (Kgs) | 10-15 | 30-40 | 60-75 | 120-150 | 150-180 | 200-230 | 250-280 | 300-330 |

| Heating Load : (kw) For Electrical Heating | 6 | 18 | 36 | 54* | 60* | * | * | * |

| Approx. steam Consumption Kgs/hr. (Steampressure 3.5 Kg. /cm2) | 15 | 25 | 50 | 100 | 130 | 170 | 200 | 250 |

| Motor (H.P.) | 2 | 5 | 10 | 15 | 20 | 20 | 25 | 30 |

| Drying Temp C* | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

| Height H1 (Approx) mm | 1600 | 1900 | 2200 | 2550 | 2600 | 2800 | 3000 | 3100 |

| Height H2 (Approx) mm | 2000 | 2250 | 3000 | 3500 | 3500 | 3900 | 4000 | 4200 |

| Width (Approx) mm | 1050 | 1400 | 1550 | 1800 | 1850 | 2000 | 2100 | 2150 |

| Lenth (Approx) mm | 800 | 1250 | 1500 | 1700 | 1700 | 2000 | 2100 | 2200 |

Applications

Documentation

Salient Features :

SPECIFICATIONS

| Model | Gross Volume | Working Volume | Power |

| Litres | Litres | H.P | |

| SSE RB 10 | 10 | 03/05/11 | 0.5 |

| SSE RB 50 | 50 | 15-20 | 1 |

| SSE RB 75 | 75 | 25-50 | 1 |

| SSE RB 150 | 150 | 70-100 | 2 |

| SSE RB 250 | 250 | 100-150 | 3 |

| SSE RB 450 | 450 | 250-300 | 5 |

| SSE RB 600 | 600 | 350-450 | 7.5 |

| SSE RB 1100 | 1100 | 750 | 10 |

| SSE RB 1500 | 1500 | 1000 | 12.5 |

| SSE RB 2000 | 2000 | 1250 | 15 |

We are instrumental in offering a wide range of Tray Dryers, which is highly appreciated for its high durability and robust construction. These Tray Dryers can be availed in various specifications as per the requirement. Moreover, we offer Tray Dryers at most competitive prices.

Finishing

The design and manufacture of the dryer is of high standard of GMP and has an aesthetic look. It is buffed externally to 150 grit matt finish and internally buffed to 220 grit mirror finish.

Electrical Heating

The Air inside the Tray Dryer is heated by "U" tube S.S.304 air heaters each of 1 KW.The heaters are fitted on the sides of the dryer to facilitate uniform heating. Maximum temperature attained inside the dryer is 100' C and will be indicated and controlled by a Digital Temperature indicator cum controller over full range of heating load.

Total Heating Load For It Will Be

The heaters will be inserted inside tubular pipe to prevent it from becoing RED HOT. The terminals of the heaters will be brought outside the dryer to make it more safe for operations for solvent based products.

Air Circulation

Air inside the dryer is circulated by one heavy duty axial flow S.S.304 or alluminum blower fitted on a shaft of and driven by l H.P. through belt. The special design of the Blower ensures uniform air circulation so that there is uniform air current over the entire charge loaded in the Trolley inside the dryer. The working of the motor is indicated by lamps in the control panel.

Trays

Trays will be manufactured from 1.6 mm SS 304 sheets.Its dimensions are 32" x 16" x 1 l/4". The Trays have rounded corners with' mirror finish from inside and outside. SS 316 quality is available on demand.

Racks And Trolleys

Racks are provided for trays insdie the Dryer. They are of fixed type for 12 and 24 Tarys Models. For 48 and 96 Trays Models. Racks are provided with wheels to slide them in and out of the Dryer. An additional S.S, trolley for Racks for outside movement can be provided on request

Model Available

Specifications

| Model | SSE TD-24 | SSE TD-48 | SSE TD-96 |

| No. Of Trays | 24 | 48 | 96 |

| Tray size | 16 x 32 x 1.25 | 16 x 32 x 1.25 | 16 x 32 x 1.25 |

| Heating load at | |||

| 100°C | 6 x1000 W | 9 x 1000 W | 15 x 1000 W |

| 200°C | 9 x1000 W | 15 x 1000 W | 21 x 1000 W |

| 300°C | 12 x1000 W | 18 x 1000 W | 27 x 1000 W |

Rotary Vacuum Dryer is suitable for drying of materials which cannot resist high temperature, material which are easily oxdised, volatile materials which should be retrieved, materials which are strong irritants and poisonous in nature. Rotary Vacuum Dryer with the improved technology integrates during operation under vacuum. The Rotary Vacuum Dryer facilitates enhanced drying efficiency, low temperature operations and economy of process by total solvent recovery. It helps cGMP based working by achieving optimum dust control, while offering advantages of efficient charging and discharging of materials. The drying unit equipped with lump breakers initially breaks large lumps and subsequently powders them (in single cone). The rotary action of the dryer together with mechanical action of the breakers, cuts down drying time and gives a lump free product.

ADVANTAGES :Technical Data

| Model | Total Volume (LTS) | Working Volume (LTS) | Heating Surface Area (SQ. MTS) | Power Required for Agitator Motor (HP) | Approx. Size of Dryer ell (Dia x Length) |

| SSE RVD-500 | 500 | 250 | 3.2 | 7.5 | 700 x 1400 |

| SSE RVD-1000 | 1000 | 500 | 6 | 10 | 900 x 1700 |

| SSE RVD-1500 | 1500 | 750 | 7.7 | 10 | 1000 x 2000 |

| SSE RVD-2000 | 2000 | 1000 | 8.7 | 15 | 1100 x 2100 |

| SSE RVD-2500 | 2500 | 1250 | 10 | 20 | 1200 x 2250 |

| SSE RVD-3000 | 3000 | 1500 | 11.6 | 20 | 1260 x 2400 |

| SSE RVD-4000 | 4000 | 2000 | 16.7 | 30 | 1200 x 3600 |

| SSE RVD-6000 | 6000 | 3000 | 17.7 | 40 | 1600 x 3000 |

| SSE RVD -8000 | 8000 | 4000 | 23.5 | 50 | 1600 x 4000 |

| SSE RVD-10000 | 10000 | 5000 | 27.3 | 60 | 1700 x 4400 |

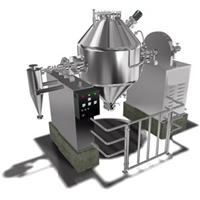

The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. All the contact parts made out of stainless steel of required grade by customer. Two third of the volume of the Cone Blender is filled to ensure proper mixing. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc.

SALIENT FEATURES :